Chloramphenicol Palmitate

| Product Code | 33404 | |||

| Quality and Standards | As per standard of Indian Pharmacopoeia | |||

| Production Capacity: Qty. |

|

|||

| Uploaded on | December 2007 |

Introduction

Chloramphenicol is the specific drug for control and cure of typhoid and broad-spectrum bacterial diseases.

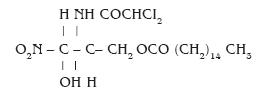

Chloramphenicol finds extensive use through tablets and capsules while chloramphenicol palmitate is used to formulate syrups. The structural formula for chloramphenicol-palmitate is represented as

It lacks the bitter taste of chloramphenicol. It is hydrolysed in the upper intestinal tract into the parent drug, however, it does not share the topical efficiency of the parent drug. Its toxicity is like that of chloramphenicol. Chloramphenicol palmitate contains 55.5-59.5% of chloramphenicol i.e. approx. 174 mg Chloramphenicolpalmitate is equivalent to 100 mg chloramphenicol. It is an anti-bacterial drug and for an adult, the equivalent of 1.5 to 3.0 g of chloramphenicol daily in divided doses is required, for a child the equivalent of 25 to 50mg of chloramphenicol per kg. of body weight daily in divided doses is required.

Market Potential

Chloramphenicol is being produced both in small scale as well as in organized sector. At present in India there are a number of units registered with Secretariat of Industrial Assistance, Deptt. of Industrial Promotion and Policy, Ministry of Commerce and Industry, Government of India, New Delhi. Export of Chloramphenicol has shown increasing trend in recent years. Looking into the demand of Chloramphenicol-palmitate and its export potential, there is a good scope for setting up units in small scale sector.

Basis and Presumptions

- The estimates are drawn for a production capacity generally considered techno economically viable for a model type of manufacturing unit.

- The cost in respect of land and building, machinery and equipment, raw materials and the selling prices of the Chloramphenicol palmitate are those generally obtained at the time of preparation of the project report and may vary depending upon other various factors.

- The wages of the workers are taken as per the prevailing labour wages laws.

- The plant, equipment and machinery required for the manufacture of chloramphenicolpalmitate is either available or can be fabricated indigenously based on the designs, drawing and specifications worked out for the project.

- Interest rate for fixed and working capital has been taken at 14%.

- Scheme is worked out on two shifts basis of eight hours a day and 300 working days in a year.

Implementation Schedule

| Preparation of Project report | 1 month |

| Selection of site | 2 months |

| SSI registration | 1 month |

| Finance/loan from bank or Financial Institution | 2 months |

| Power connection/building construction | 3 months |

| Machinery procurement | 3 months |

| Trial run | 2 weeks |

| Actual Commercial Production | 1 month |

Technical Aspects

Process of Manufacture

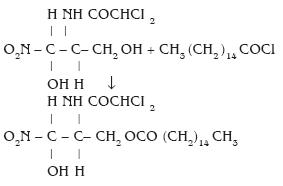

Chloramphenicol is esterified by condensing with palmitoyl chloride (CH3 (CH2)14 COCI) in the presence of pyridine. The crude ester is obtained by pouring the reaction product into a large excess of diluted Hydrochloric acid and the whole mass is filtered. It is then washed with toluene dimethyl formamide. The pure ester is dried, recrystallised and pulverized before packing. Chemical equation of the reaction is as under.

Quality Control and Standards

Chloramphenicol-palmitate is practically insoluble in water, slightly soluble in alcohol, soluble in acetone, chloroform and solvent ether. It is fine white or greyish white powder, it melts between 870 to 950C. It should conform to the Standard of Indian Pharmacopoeia.

Production Capacity (per annum)

| Installed capacity | 8 MT |

| Value | 92,00,000 |

Financial Aspects

Fixed Capital

(i) Land and Building Value

(Rs.) |

|

| Land 1000 sq mtrs. @ Rs. 3000 per sq.mtr | 3000000 |

| Building (Office, Store, working sheds, Boiler Room, Laboratory etc.) 600 sq. mtrs @ Rs 5000 per sq.mtr | 3000000 |

| Bore well | 100000 |

| Total | 6100000 |

(ii) Machinery and Equipments

Equipments |

Qty. |

Value (Rs.) |

| Stainless steel reactors (500 litres capacity) equipped with a reflux condenser and jacket for steam heating. | 2 | 500000 |

| Air circulated steam heated coiled tray drier, with vacuum drying system. | 1 | 190000 |

| Demineralised water plant | 1 | 60000 |

| Storage tanks for toluence/ dimethyl-formamide and Hydrochlomic acid | 2 | 230000 |

| Boiler | 1 | 150000 |

| Filteration unit | 1 | 120000 |

| Pulveriser | 1 | 65000 |

| Laboratory equipments (Spectrophotometer, Thin layer chromatography Centrifuge, oven and other laboratory glassware and equipments | 300000 | |

| Total | 1615000 | |

| Erection charge @ 10% of the cost of machinery and equipments | 161500 | |

| Office furniture and equipments | 80000 | |

| Pre-operative expenses | 40000 | |

| Total | 1896500 |

(iii) Total Fixed Capital

(Rs.) |

|

| Land & Building | 6100000 |

| Plant & Machinery | 1896500 |

| Total | 7996500 |

Working Capital (per month)

(i) Personnel

Designation |

No. |

Salary |

Amount (Rs.) |

| Chemist/Pharmacist | 1 | 10000 | 10000 |

| Manager/commercial Assistant | 1 | 9000 | 9000 |

| Analytical Chemist | 1 | 8000 | 8000 |

| Sales Representative | 2 | 8000 | 16000 |

| Accountant/ Clerk | 2 | 5000 | 10000 |

| Skilled Workers | 4 | 4000 | 16000 |

| Semi-skilled Workers | 3 | 3000 | 9000 |

| Boiler Attendant | 1 | 5000 | 5000 |

| Watchman and Peon | 2 | 3000 | 6000 |

| Total | 89000 | ||

| Perquisites @ 22% | 19580 | ||

| Total | 108580 |

(ii) Raw Materials Including Packaging Requirement (per month)

Particulars |

Ind./I/Imp. |

Qty. Kg. |

Rate (Rs.) |

Value (Rs.) |

| Chloramphenicol | Ind. | 405 | 1500 | 607500 |

| Palmitoyl Chloride | do | 324 | 140 | 45360 |

| Chemicals like pyridine Toluene, dimethyl formamide | do | LS | 50000 | |

| Packing material | LS | 15000 | ||

| Total | 717860 |

(iii) Utilities (per month)

(Rs.) |

|

| Electricity and fuel | 40000 |

| Total | 40000 |

(iv) Other Expenses (per month)

(Rs.) |

|

| Postage and stationery | 2000 |

| Telephone | 3000 |

| Consumable stores | 4000 |

| Repairs and maintenance | 3000 |

| Transportation | 5000 |

| Advertisement and publicity | 5000 |

| Insurance | 700 |

| Miscellaneous | 5000 |

| Total | 27700 |

B. Working Capital (per month)

| Raw Material | 717860 |

| Salary and wages | 108580 |

| Utilities and other expenses | 67700 |

| Total | 894140 |

| Working Capital (for 2 Months) | 1788280 |

C. Total Capital Investment

| Working capital for 2 month | 1788280 |

| Land and Building | 6100000 |

| Machinery and Equipments | 1896500 |

| Total | 9784780 |

Financial Analysis

Cost of Production |

(Rs) |

| Working capital for 1 year | 10729680 |

| Depreciation on building @ 5% | 305000 |

| Depreciation on machineries and equipments @ 10% | 181650 |

| Depreciation on office furniture and equipments @ 20% | 16000 |

| Interest on total Capital investment @ 14% | 1369869 |

| Total | 12602199 |

Sales Turnover (per annum)

Item |

Qty. |

Rate (Rs) |

Value (Rs) |

| Chloramphenicol-palmitate | 8M.T. | 1700 | 13600000 |

Net Profit (per annum)Profit

Sale turnover – Cost of production |

Net Profit Ratio

Net profit per year × 100 ——————————— Sales turnover |

|

7.34 |

Rate of Return

Net profit per year × 100 ——————————— Capital investment |

|

10.2 |

Break-even Point

Fixed Cost |

(Rs.) |

| Depreciation on machinery and equipment | 181650 |

| Insurance | 8400 |

| Depreciation on building | 305000 |

| Interest on total capital investment | 1369869 |

| 40% of other contingent expenses | 321600 |

| 40% of salary and wages | 43432 |

| Total | 2229951 |

| B.E.P. | Fixed cost × 100 Fixed cost + profit

|

= 69.09 |

Addresses of Machinery and Equipment Suppliers

- M/s. Chemical Plant and Equipments

Naroda, GIDC,

Ahmedabad, (Gujarat) - M/s. Cadmach Machinery

GIDC, Phase IV, Vatva,

Ahmedabad. - M/s.Sethi Engineering Works

27/772, Zorawar Singh Marg,

New Delhi.

- M/s. Rank and Co.

Wazirpur Industrial Area,

New Delhi-110052.

Addresses Raw Material Suppliers

- M/s. National Solvent Corporation

Devi Dayal Road,

Muland,

Mumbai. - M/s. Excel India Ltd.

184-187 S.V Road,

Jogeshwari,

Mumbai. - M/s. Cemet Ltd.

214, Hans Bhawan,

Wing No. 1,

Bahadur Shah Zafar Marg,

New Delhi. - M/s. Manish Organic Ltd.

National Chambers,

Ashram Road,

Ahmedabad.

For further information please contact

Information Manager

TIMEIS Project

E-mail: timeis@ficci.com