Apparatus for Measuring Sieve Dimensions

Introduction

Industries such as cement and drug manufacturing require powders of constant and homogeneous particle size, which are obtained from sieves. The sieves are wire mesh, normally made of metal wires of various diameters with a variety of spacing, depending on the required size of the sieved powder. It is therefore of critical importance to know a priori, the uniformity of spacing and the possibility of any microscopic deformation in the sieve. Presently known method like on line measurement using optical Fourier transform do not preserve the details of the object such as cracks, holes, discontinuous patterns, etc. Another known method making use of laser beam also cannot locate these types of defects. In order to overcome these shortcomings and also to devise a means for accurate measurement of sieve parameters for critical applications, a new methodology using image processing and wavelet transform has been developed.

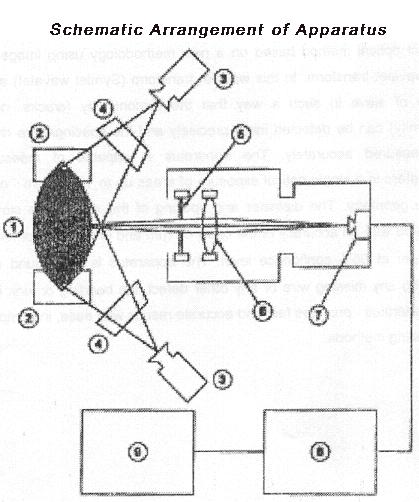

The apparatus measures sieve dimensions by non-contact optical method. A schematic arrangement of the apparatus is given in the Enclosure. Tshe sieve in frame

- Is removably fixed to a holder

- Such that the sieve is held in position and the sieve may be translated in x,y,z, directions for alignment of sieve to light beam. The said sieve is illuminated completely and uniformly by a set of light sources

- Through a set of diffusers.

- An optical arrangement capable of converting optical signal to electronic signal is provided in front of the sieve. The optical arrangement comprises of a known conventional Charge Coupled Device (CCD)

- and a conventional focusing lens

- The electronic signal output of the CCD is fed to an image grabing unit

- To receive light reflected from the sieve selected through an iris

- and then to a computer

- Having neccessary image processing software for analysis of captured optical image. The rate of image transfer from CCD via image grabbing unit to the computer is of the order of 30 frames/second. The captured image is stored in the computer in a two dimensional array.

The apparatus is capable of analyzing charcteristics of a large area siceve in a single run. This has been achieved by using at least two light sources angularly placed with respect to sieve.

Salient features

Apparatus is simple to use without eye fatigue. Gives simultaneously both the diameter of wire and wire spacing. Diameter and spacing of the wire in the sieves can be measured with an accuracy of 1 µm and .uncertainty measurement of ± 2 µm at 95% confidence level Capable of measuring sieve parameters i.e. size and spacing of wire sieves, in a single optial exposure of areas, upto 100 Sq. cm. Of circular or square geometry. Measurement of complete sieve characteristics could be completed within a duration of 30 minutes. Can detect any missing wire or any other defect like bending or kink in the wire. Provide fast and accurate results with ease.

Prospective Users

All industries using material in powder form after crushing and grinding the raw material

Keywords

Sieve, Optical, Image, Signal

Type of Technology

Device with Software

Developed by : Prof. Sekahar Chandra & Dr. Shashi Singh

Department: Instrument Design Development

For further information please contact

Managing Director

Foundation for Innovation and Technology Transfer (FITT)

Indian Institute of Technology, Delhi

Hauz Khas, New Delhi-110016, INDIA

Tel : 91-011-26597167, 26857762, 26581013, 26597153

Fax : 91-011-26851169

E-mail : drkdpn@gmail.com